If you have arcs or round corners or circles cut unsmoothly or there’re waves on the curves, you can adjust software parameter first then check part status as below. Regular maintenance is very important.

1. Please check software parameters first.

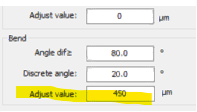

1.1 Check Bend Adjust Value

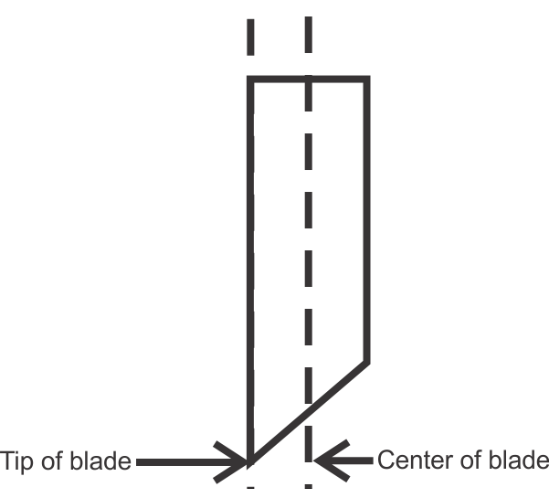

Bend Adjust Value means blade tip offset, which is a distance between blade axis and blade tip.

If the value is too small, there can be some waves on the circle. Please use 450~500micron value, when using 10U45 knives.

1.2 Check Accelleration

If you are running the machine at too high speed, it can cause bad circular cutting. Try to reduce the Cut acceleration and Move accelleration to 300 and bend accelleration to 60 or lower.

Bend accelleration is the most important. Default value is 60, but try to reduce it for smoother curves.

1.3 Check nodes of original cut file (PLT).

It is highly recomended to convert AI or PLT file by using our new DUOCONV software.

2. Check hardware parts

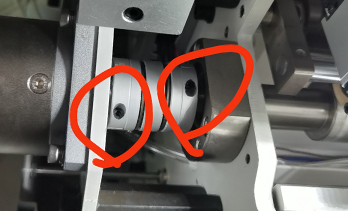

Please check Cam Coupler Connectors. They are very important parts, to drive X and Y axis by servo motors. Please check if they are loosened and fasten them strong enough.

2.1 Pls clean blade holder regularly. Long hours of work can contaminate knife, knife holder hole and knife holder bearing by glue residue or paper scraps. It causes inflexible blade rotating inflexible. Also please replace ‘spring’ when you change blade at the same time. Spring is also consumable. It also helps to add one drop of lubricant onto the blade holder bearing.

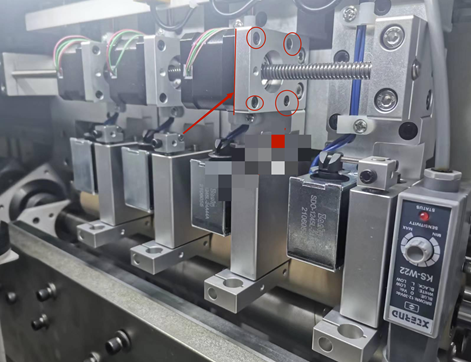

2.2 The gap between the pitcher motor and the screw rod can be too big. To fasten this part, a copper pad is needed on the motor fixing plate. Loosen the four fixing screws and insert the copper pad on the red line in below photo, between plate and motor, and fasten 4 bolts rigidly.

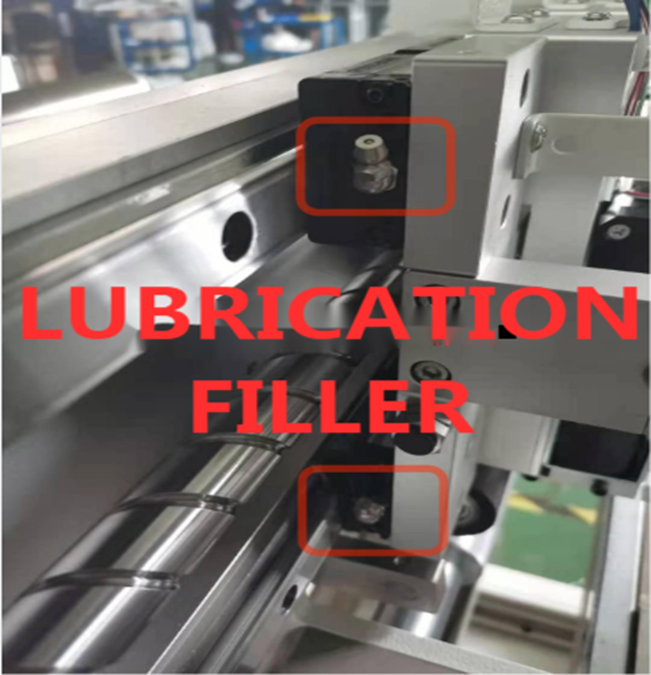

2.3 Do regular maintenence.

Linear rail sliding system needs to be lubricated regularly (at least quarterly).

You can use lubrication oil (Type 00 grease, to filler of sliders).

Clean the guide rail with dust-free cloth and spray WD-40.

![DUOBLADE WX [TIPS] : When you want max. speed of cutting?](https://valloy.com/wp-content/uploads/2024/01/268f644429ce4db2ece8e2f7a2858835-500x383.png)

![DUOBLADE WX [Tips] : What is “PAUSE, NO PAPER” error?](https://valloy.com/wp-content/uploads/2024/01/2f83a1507cc9626eab2d78936121c170-500x383.png)

![DUOBLADE WX [Tips] : Media loss at starting and roll changing](https://valloy.com/wp-content/uploads/2024/01/99438afb5e9d6d530bc2cd4609ed791b-500x383.png)

![DUOBLADE WX [Tips] : Interval no. vs Track no.](https://valloy.com/wp-content/uploads/2024/01/6394dee19b914e6b3b6f7fbf65d4c224-500x383.png)