To keep the machine in good condition all the time, regular maintenance is important.

-

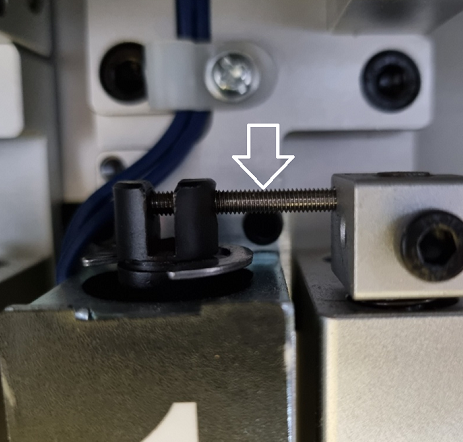

Solenoid Sync Bolt

Problem : bolt can be bent and pressure can be irregular

Service Interval : Yearly / half a year with heavy usage

Maintenance supplies : new replacement

-

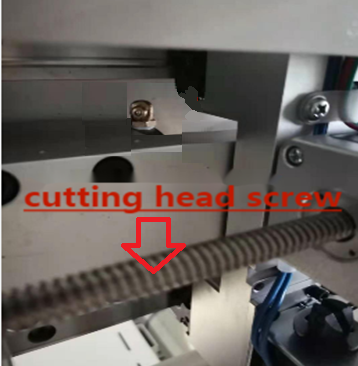

Head Screw

Problem : noise and resistance during head distance adjustment

Service Interval : quarterly

Maintenance supplies : Adding of lubrication oil

-

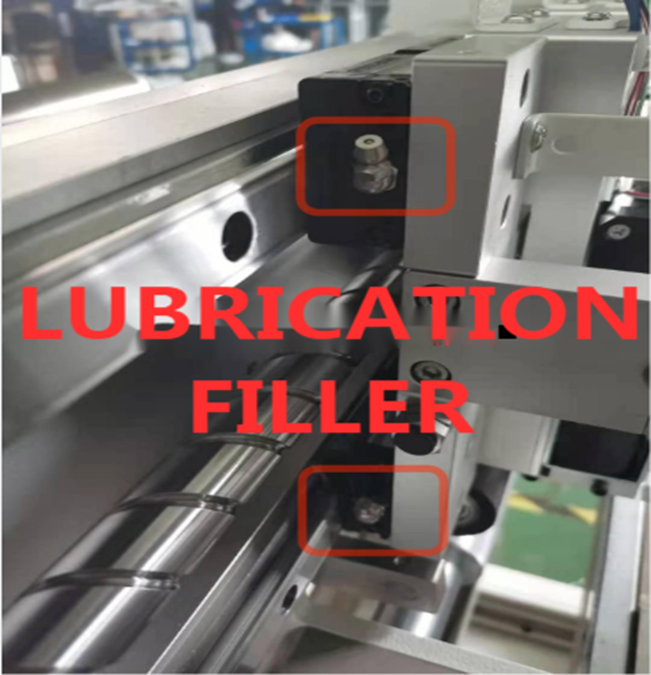

Y movement linear rail sliding system

Problem : noise and resistance during head movement

Service Interval : quarterly

Maintenance supplies : Adding of lubrication oil (Type 00 grease, to filler of sliders)

Clean the guide rail with dust-free cloth and spray WD-40

-

Air Rodless Cylinder

Problem : resistance during tension bar movement

Service Interval : monthly in dusty environment / otherwise quarterly

Maintenance supplies : Clean the cylinder surface with a clean cloth using WD-40

-

Atomizer

Problem : ran out of oil

Service Interval : quarterly

Maintenance supplies : Open the atomizer switch gently to prevent oil from entering the air pipe then fill oil to the level of center line in the container

-

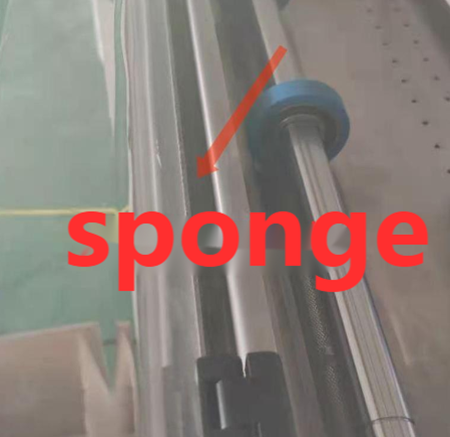

Sheet cutter sponge

Problem : Contamination of sheet cutter

Service Interval : dependant on frequency of sheet cutter usage / if every job requires sheet cutting then perform service monthly

Maintenance supplies : Add lubrication oil on the sponge and clean the residual glue and paper ash on the surface of the cutter regularly

-

Sheeter stopping screw

Problem : Not smooth movement of sheet cutting blade

Service Interval : dependant on frequency of sheet cutter usage / if every job requires sheet cutting then perform service quarterly

Maintenance supplies : Add white lithium grease regularly onto the bolt

-

Bearing of rolling shafts

Problem : Not smooth movement of roller rotation

Service Interval : half a year

Maintenance supplies : Clean the surface with a clean cloth using WD-40

![DUOBLADE WX [TIPS] : When you want max. speed of cutting?](https://valloy.com/wp-content/uploads/2024/01/268f644429ce4db2ece8e2f7a2858835-500x383.png)

![DUOBLADE WX [Tips] : What is “PAUSE, NO PAPER” error?](https://valloy.com/wp-content/uploads/2024/01/2f83a1507cc9626eab2d78936121c170-500x383.png)

![DUOBLADE WX [Tips] : Media loss at starting and roll changing](https://valloy.com/wp-content/uploads/2024/01/99438afb5e9d6d530bc2cd4609ed791b-500x383.png)

![DUOBLADE WX [Tips] : Interval no. vs Track no.](https://valloy.com/wp-content/uploads/2024/01/6394dee19b914e6b3b6f7fbf65d4c224-500x383.png)