When you have different cutting depth partly, it can be caused by instable pressure of cutting head solenoid. Head up/down movement pressure can be irregular due to the bent bolts of solenoid part. Long bolt to synchronize movement of solenoid and knife holder is a kind of consumable and you need to replace it when you have this kind of issue. Please refer to below linked note for this problem.

(We pack about 20 bolts together with spare knives together when shipping.)

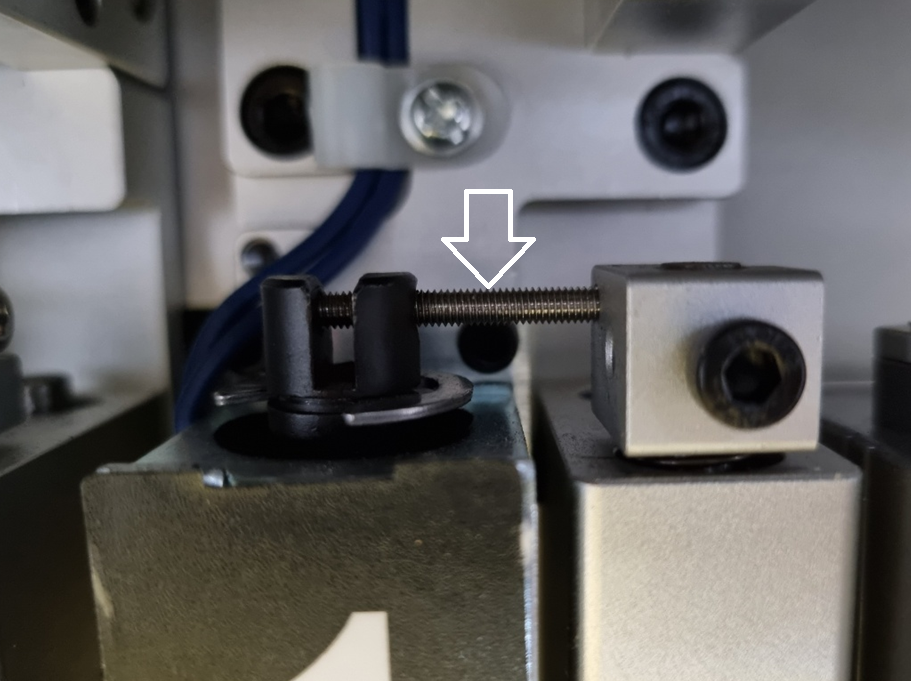

The screw pointed by arrow in below photo should be replaced regularly.

After a long time of use, these long bolts can be bent, resulting in no gaps in the electromagnets,.

So there can be some errors in the limit of the knife seat when moving up and down.

Then depth/pressure related problems can happen. Cutting depth can vary or cut line trace can be shown at starting or ending.

You are advised to replace this long bolt every 6 month or every year.

Or you can change it when you find instable cutting depth and pressure.

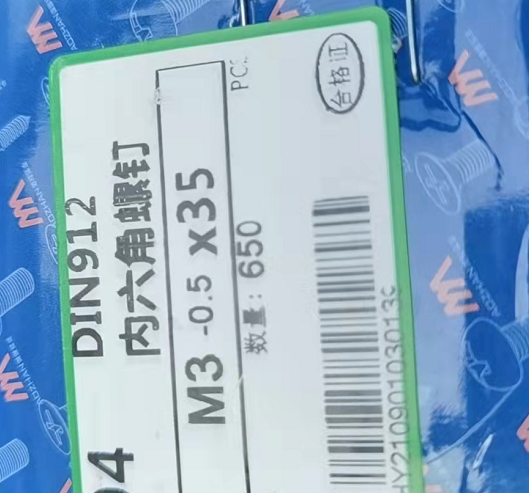

You can find this bold in the market : M3X35MM

![DUOBLADE WX [TIPS] : When you want max. speed of cutting?](https://valloy.com/wp-content/uploads/2024/01/268f644429ce4db2ece8e2f7a2858835-500x383.png)

![DUOBLADE WX [Tips] : What is “PAUSE, NO PAPER” error?](https://valloy.com/wp-content/uploads/2024/01/2f83a1507cc9626eab2d78936121c170-500x383.png)

![DUOBLADE WX [Tips] : Media loss at starting and roll changing](https://valloy.com/wp-content/uploads/2024/01/99438afb5e9d6d530bc2cd4609ed791b-500x383.png)

![DUOBLADE WX [Tips] : Interval no. vs Track no.](https://valloy.com/wp-content/uploads/2024/01/6394dee19b914e6b3b6f7fbf65d4c224-500x383.png)