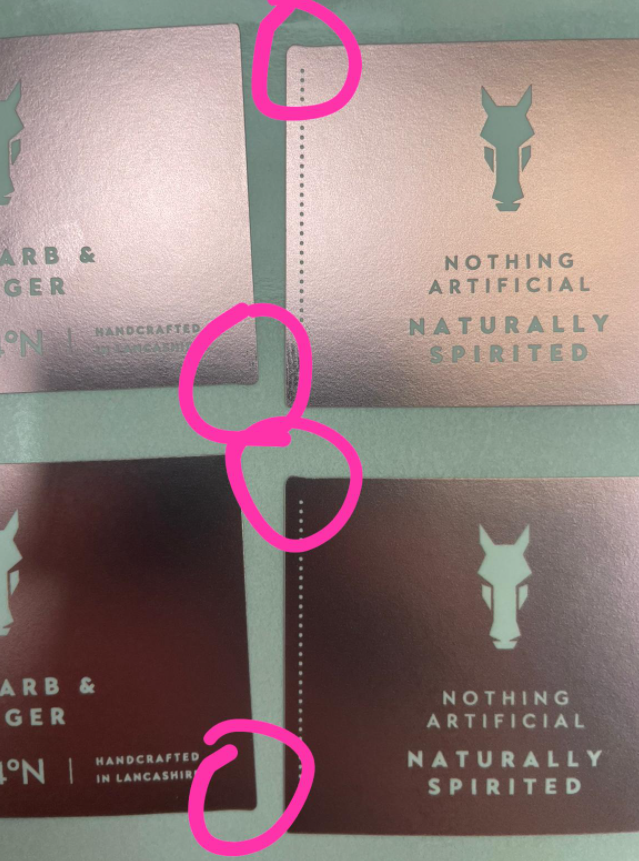

You can meet overshooting problem at corners during cutting.

This problem can be minimized by reducing cutting speed and accelleration values.

However, fundamental reasion is because of the characteristing of cutting knife.

Dragging knife has a descrete space between knife tip and center of the knife.

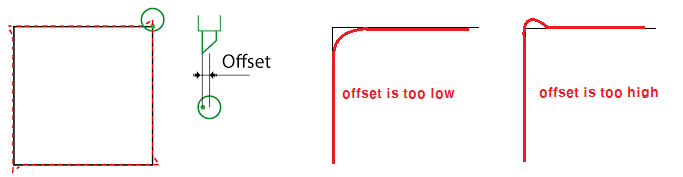

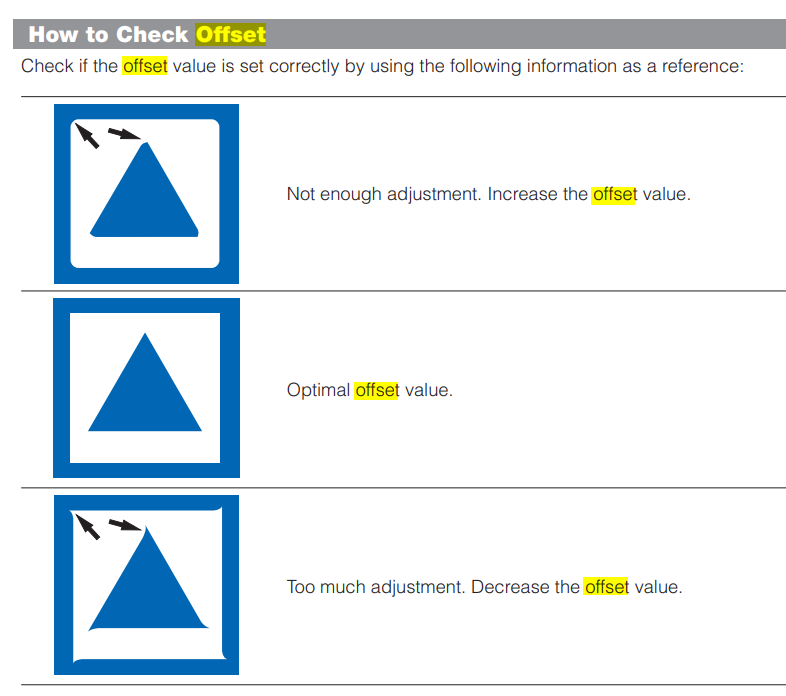

Tip rotates at corder driven by movement of knife axis at center, so this dragging error needs to be compensated. We call this as offset.

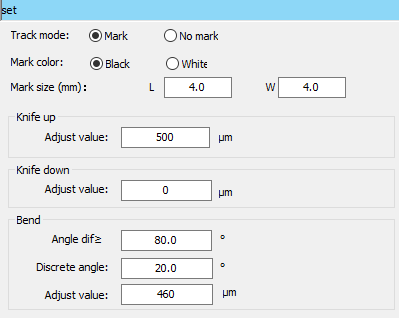

In DuoBlade WX, you can find related parameter at “BEND” compensation menu.

-

Angle difference : when angle of change at corner is larger than this value, compensation will be applied. Angle control is performed when the change amount of an angle is equal to or more than the value that you set. If a small value is set, angle control is performed frequently for some image shapes and, therefore, the quality is improved but cut time becomes longer. On the other hand, a large offset angle value reduces the cut time but an image different from the intended one may be cut.

-

Discrete angle : this is threshold of angle compensation. So the larger value, the lower the precision; the smaller value, the higher the precision.

-

Adjust value: This is offset value. 400 micron for 9U45 knife and 470 mocron for 10U45. However it is also dependent to paper thickness and toughness, so you need to find optimal value by trials and errors.

* Note: This setting must be done before saving the file.

![DUOBLADE WX [TIPS] : When you want max. speed of cutting?](https://valloy.com/wp-content/uploads/2024/01/268f644429ce4db2ece8e2f7a2858835-500x383.png)

![DUOBLADE WX [Tips] : What is “PAUSE, NO PAPER” error?](https://valloy.com/wp-content/uploads/2024/01/2f83a1507cc9626eab2d78936121c170-500x383.png)

![DUOBLADE WX [Tips] : Media loss at starting and roll changing](https://valloy.com/wp-content/uploads/2024/01/99438afb5e9d6d530bc2cd4609ed791b-500x383.png)

![DUOBLADE WX [Tips] : Interval no. vs Track no.](https://valloy.com/wp-content/uploads/2024/01/6394dee19b914e6b3b6f7fbf65d4c224-500x383.png)