Cut all your goods faster like a laser die-cutting machine, but without burn mark!

Digital wind blows in label finisher machine market, too!

New marketing tools are attracting attention as the digital breeze blows in the printing market. According to the industry, the digital printing market is expected to increase by 15%. In digital printing technology, productivity is high when printing a small quantity, and it is possible to save time and money by easy operation.It is also easy to use for customer sending DM and invoices that change contents only in the same form. In addition, there is a growing demand for barcodes for inventory management, tracking of distribution information, and capacity changes, as well as trace ability through label printing in the case of counterfeiting, theft or theft of products.Variable data label companies expect that the use of variable data will continue to increase in the digital printing market in the future.

Variable data is often printed in a small quantity of various types, and accordingly, it is becoming a digital post-processing equipment that mainly manufactures a small quantity of digital label finisher. In analog label market, Thomson blade have to create depending on label shapes and size and it is not good for small quantity batch production labels. but now, in digital market, the story is different.It cuts all the die-lines by using the blade and the laser. It doesn’t have to make a new blade for new shapes, new sizes and as a result, it saves money and the time.

Of course, they have each have advantage sand disadvantages. For digital laser label cutters, it boasts cutting speeds from 5 m / min to a maximum of 15 m / min.In addition, it is equipped with a mechanism for laminating, slitting and so on, so it is an all-in-one label cutting machine that combines speed.. but this laser die-cutting machine has a disadvantage.laser make a burn mark (or it is called white edge in films) in outside of labels after cutting and it is the biggest reason that people cannot replace the laser die-cutting machine from Thomson finisher easily. The cost is also expensive.

In the way, the digital blade label cutters do not make burn mark or white edge like laser label cutter, and are very clean and sophisticated. However, most roll-to-roll label post-processor speeds are on average 1 to 2 meters per minute, which is a very slow speed to produce commercial labels.It is very difficult options. Users have to choice between speedy cutting even if it makes burn mark (or white edge) or clear cutting result considering slow speed.

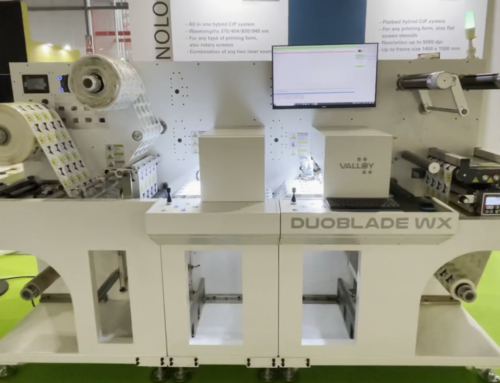

To complement this, Valloy Inc. Has released DUOBLADE S, which can be used with up to four blades mounted simultaneously in the second half of 2018. DUOBLADE S is an all-in-one digital post-processing machine that uses the same speed of 5 m / min as the normal speed of laser and can complete roll to roll total label finisher from laminating to slitting and grasping at once.

In particular, the 2nd Rewinder used for slitting is built in, so users do not have to pay extra for the optional 2nd Rewinder. The DUOBLADE S, which is praised as the world’s fastest digital blade label cutting machine at a speed of 5 m / min from the moment of its launch, releases and sells DUOBLADE SX which is upgraded DUOBLADE S in the second half of 2018. Cutting speed, which is the biggest advantage of DUOBLADE S, is now faster and more precise cutting is possible with the high-speed servo motor which is double the capacity of S. By applying a pneumatic core fixing system to the unwinder and rewinder, each core can be independently controlled on the operator.

In addition, to compensate for the inconvenience of having to move the position of each slitter one by one, it has been upgraded to control the slitting bar so that the entire slitting bar can be moved to set its position. And it can control the pressure of cutting head independently as well as real time cutting pressure adjustment, and supports full cut and half cut simultaneously.Also, to reduce media installation time specific to the roll-to-roll device, the media attaching plate is installed to enhance the user’s convenience. “DUOBLADE SX with faster speed, sophistication and user friendliness ”DUOBLADE SX will go beyond the reputation of DUOBLADE S, the steady seller of Valloy, and look forward to opening up a new era of label post-processing machines for small batches.

![]()

Valloy Incorporation

Rm 1017, DaeMyung Valeon, 127 Beobwon-ro, Songpa-gu, Seoul, 05836 KOREA

Tel : +82-2-6082-5022 Fax : +82-2-445-5441 Email : [email protected]

Web : www.valloy.com

Leave A Comment

You must be logged in to post a comment.