View of flexible package printing and beverage printing

According to a report by Smithers Pira, the market for packaging materials is growing rapidly at a rate of 3% a year, and the total industry size is expected to reach as high as $ 248 billion by 2020. In terms of usage, the food industry is much larger, but the beverage division has started to apply flexible packaging materials to various products. Products such as wine, juice, frozen cocktails and energy drinks are increasingly being packaged in pouches, with a growing trend in the number of small caps for one person.

Consumers prefer a portable and convenient pouch on the move, and it is advantageous in that they can be brought to places where glass bottles are not allowed, such as sports arenas and beaches.

As the various shapes and sizes have been developed for children, track-running athletes, etc., pouch packaging has been ergonomically developed and improved in convenience.

In the meantime, the beverage industry has been providing pouches with straws for many years. It was generally used as a straw to be inserted into a small foil hole in a single carton, but nowadays, a cap that can be closed again has appeared so that the consumer can open and open the lid again. Laminate has also been improved to effectively block the deterioration of oxygen and sunlight to increase the shelf life of the film is attached to flexible packaging material options. Beverage quality.

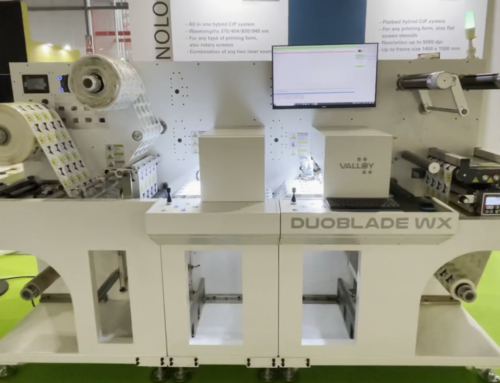

<13″ digital roll to roll label press BIZPRESS 13R>

VALLOY Inc. has launched BIZPRESS 13R, a digital label printer that can print flexible packaging materials regardless of heat or static electricity, in order to prepare for evolving flexible packaging and beverage packaging printing. Generally, digital printing requires a high temperature of 200 degrees and it is difficult to print on metal or film materials which are sensitive to electricity because it is based on electrostatic method. To overcome this limitation of digital printing, BIZPRESS 13R uses EA-ECO toner printing with low temperature to prevent the damage of the fuser. In addition, Ionizer is installed to remove the static electricity laser pointer when printing on film materials. as a result, it can print on most of materials with the best quality, even though it is a digital printing machine. The exclusive software supports print variable data printing like QR code, 2D barcode and LOT number, serial numbers. And it prints regardless of the amount of printing.

The limitation of the digital printing method are finally breaking one by one. and Valloy is on top of that. Trigger already pulled. you don’t have to find the printing solution for flexible packaging printer. BIZPRESS 13R will be the best solution with the material compatibility and fast printing speed.

Valloy Incorporation

Rm 1017, DaeMyung Valeon, 127 Beobwon-ro, Songpa-gu, Seoul, 05836 KOREA

Tel : +82-2-6082-5022 Fax : +82-2-445-5441 Email : [email protected]

Web : www.valloy.com

Leave A Comment

You must be logged in to post a comment.